You May Be Looking For ..

PRODUCTS

Furniture testing equipment

Bathroom testing equipment

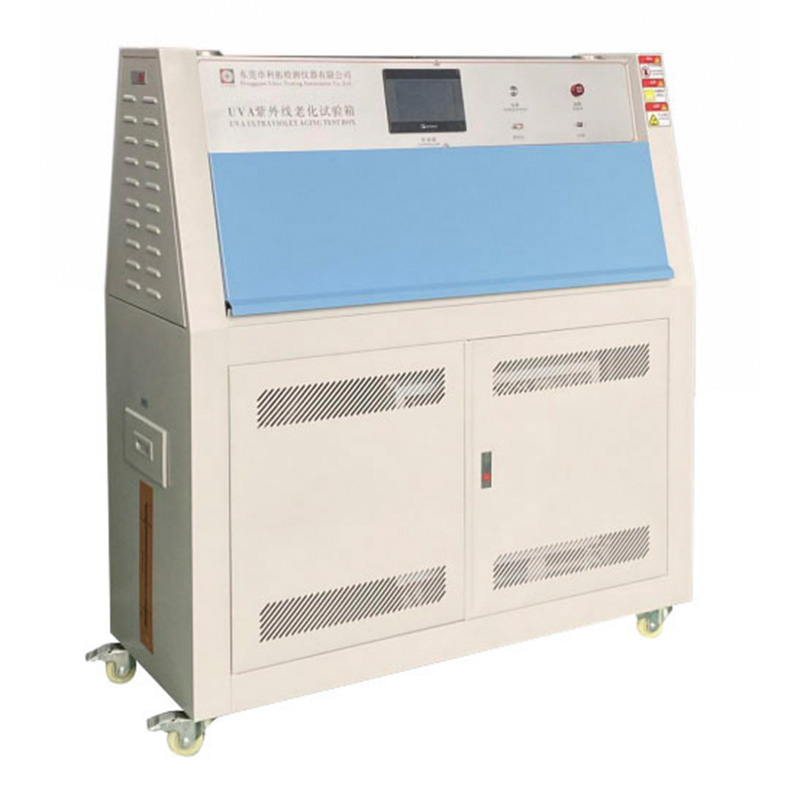

Environmental testing machine

Sports equipment testing machine

Building material testing equipment

Packaging and transportation testing machine

Tensile testing machine

Office stationery testing equipment

Battery testing equipment

Paper printing testing equipment

Mobile phone detection equipment

Toy testing equipment

Fabric leather testing equipment