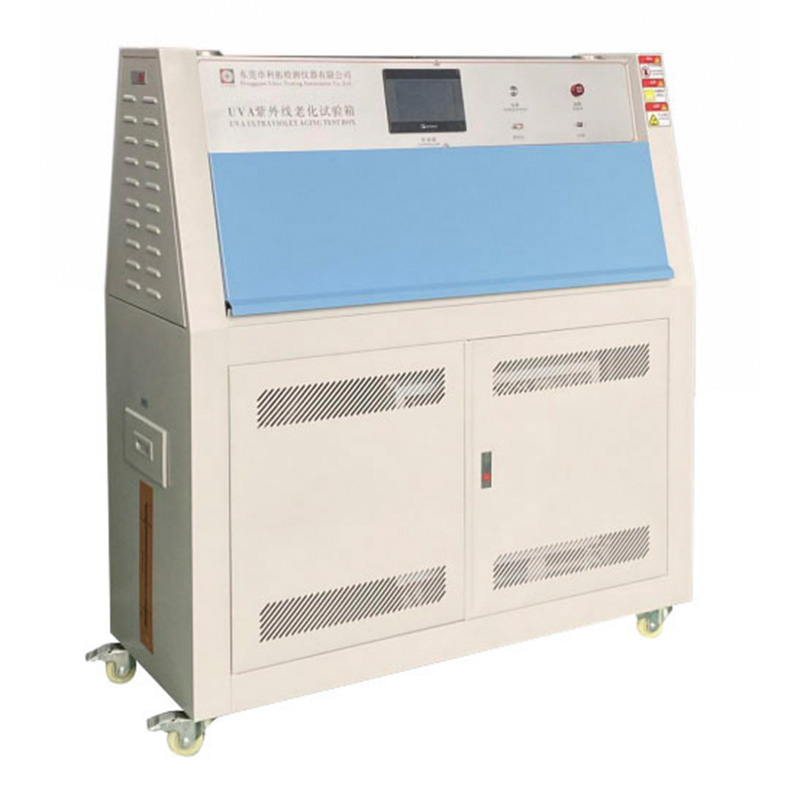

Product description

Uv Weathering Test Machine is the world's most widely used ,can be used in more labs throughout the world than any other accelerated weathering tester. It's used widely in the industry, such as printing ink, paint, pastics, print, packaging,motor van, metal, electron, medical, and so on.

Uv Weathering Test Machine ,simulates damaging effects of long term outdoor exposure of materials and coatings by exposing test samples to varying conditions of the most aggressive components of weathering - ultraviolet radiation, moisture and heat. A UV accelerated weathering chamber uses fluorecent lamps to provide a radiation spectrum centered in the ultraviolet wavelengths. Moisture is provided by forced condensation, and temperature is controlled by heaters.

Technical parameters

| 1. Temperature range: RT room temperature ~ +70ºC |

| 2. Humidity range: >=90%RH |

| 3. Temperature uniformity: <=±2ºC |

| 4. Temperature fluctuation: ±0.5ºC |

| 5. Lamp center distance: 70mm |

| 6. Distance between the test product and the center of the lamp: 50mm |

| 7.Irradiance: adjustable within 0.1 ~ 0.89W/m2 |

| 8. The test period of light, condensation and spray can be adjusted |

| 9. Lamp: UVA340 lamp, L=1200/40W (import), 8 (UVA service life more than 1600h) |

| 10. Controller: Color touch screen China Taiwan (Willuntong) intelligent controller |

| 11. Temperature control mode: PID self-tuning SSR control |

| 12.Water depth: 25mm automatic control |

| 13.Effective irradiation area: 900×450mm |

| 14.Ultraviolet wavelength: UVA range is 315 ~ 400nm |

| 15.Test time: 0 ~ 9999H(adjustable) |

| 16.Irradiation blackboard temperature: +50ºC ~ +70ºC |

| 17.Unit functions: light, condensation, rain |

| 18.Internal dimensions: W1100*D500*H500 (mm) |

| 19.External dimensions (approx) : W1350*D650*H1550 (mm) |

| 20.Case material: a. Outer box material: Baosteel high-quality steel plate electrostatic spray treatment; b. Inner box material: 1.2mm thick SUS304# heat-resistant and cold-resistant stainless steel plate. c. The box is made of CNC equipment, advanced technology, smooth lines, beautiful and generous d. The air duct in the box adopts a single circulation system, and has an imported axial flow fan, which improves the flow brightness and heating ability of the air The amplitude improves the temperature uniformity in the test chamber. e. The heating method is the inner tank type heating, fast heating and uniform temperature distribution. f. The lid is bidirectional clamshell type, easy to close. g. The water level of the inner tank is automatically replenishing, preventing the heating tube from being damaged by air burning. h. The sample holder is made of stainless steel or aluminum alloy i. The bottom of the unit is fixed with high-quality PU movable wheels j. The drainage system uses U-shaped sedimentation device to drain k. The surface of the test sample is parallel to the plane of the UV lamp. The spray system is equipped with automatic sprinkler heads and adjustable water pressure |

| 21.System noise: ≤68dB (500mm from the surface of the equipment and operating bit, respectively) |

| 22.Cooling method: water-cooled (customers provide frozen water |

| 23.Inlet flow rate: ≤2m³/H |

| 24.Water inlet temperature: 5-32ºC |

| 25.Inlet pressure: 0.2MPa |

| 26.Environment heat dissipation: ≤0.3KW |

| 27.Equipment fault protection: overheat protection circuit breaker, humidification system overheat protection, compressor overload protection, control system overload protection Protection, overload indicator light, phase sequence protection, water shortage protection, high pressure and low pressure protection, over temperature protection, water supply delay protection, fan overcurrent protection. |

Equipment characteristics

1. Better simulation of the ultraviolet band in sunlight.

2. Irradiance closed-loop control system, continuous monitoring, fast calibration.

3. Simulate condensation consistent with natural wet environment.

4. UV340 lamp with good correlation.

5. Spectrum stability, lamp life 1600 hours.

6. Less maintenance and low operating costs.

Last Article:Yellowing Resistance Test Chamber

Next Article:Salt Spray Testing Machine