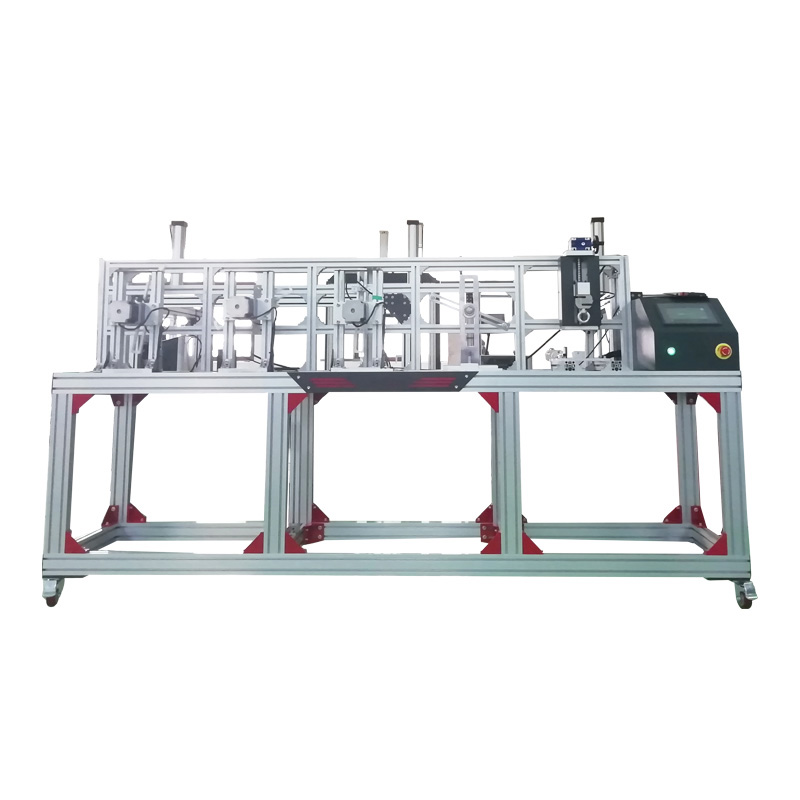

Product description

Professional testing equipment specially designed for inspecting the multi-point interlocking locking system of modern building doors and Windows. This equipment conducts a comprehensive assessment of the overall coordination, durability and reliability of the multi-point locking system by simulating the repeated opening and closing conditions of doors and Windows during long-term use, ensuring that the product meets the high-standard performance requirements of building doors and windows.

Technical parameters

1. Structure: Aluminum profiles

2. Applicable to multi-point lockers for sliding doors and Windows

3. Transmission mode: Rotary cylinder + push-pull cylinder

4. Torsion Angle: Adjustable from 0 to 180 degrees

5. Torsion speed: Adjustable from 0 to 20 times per minute

6. Weights: 10N

7. Control mode: PLC+ touch screen

8. Volume: Length 1.5* Width 0.7* Height 1.8 meters

9. Power Supply: AC220V, 50HZ

Comply with the standards and terms

| Category | Standard name | Standard clauses |

| Multi-point locking device for building door and window hardware | JG/T 215-2017 | 4.4.2 Repeated opening and closing |

| Multi-point locking device for building door and window hardware | JG/T 215-2017 | 5.4.2 Repeated opening and closing |

Test method

4.4.2 Repeated opening and closing

After being repeatedly opened and closed 25,000 times, the operation was normal and it did not affect normal use. And it should satisfy the following

a) The operating torque of the gear-driven multi-point lockout should not exceed 1 N·m; The sliding force of the multi-point lock driven by the connecting rod should not exceed 15 N.

b) The wear of the working surface at the locking points and lock seats should not exceed 1 mm.

5.4.2 Repeated opening and closing

Install the multi-point lockers on the test simulation doors and Windows of appropriate dimensions according to the actual usage conditions for testing, respectively in the direction parallel to the window sash and perpendicular to the door and window sash

Apply a force of 10N simultaneously in the direction, with a test frequency ranging from 250 times /h to 275 times /h. After completing 5,000 test cycles, check and lubricate as required by the product manual.

Last Article:Single-point locker fatigue testing machine

Next Article:Fatigue Testing Machine for Transmission and Flat Open Lock Device (Two Stations)