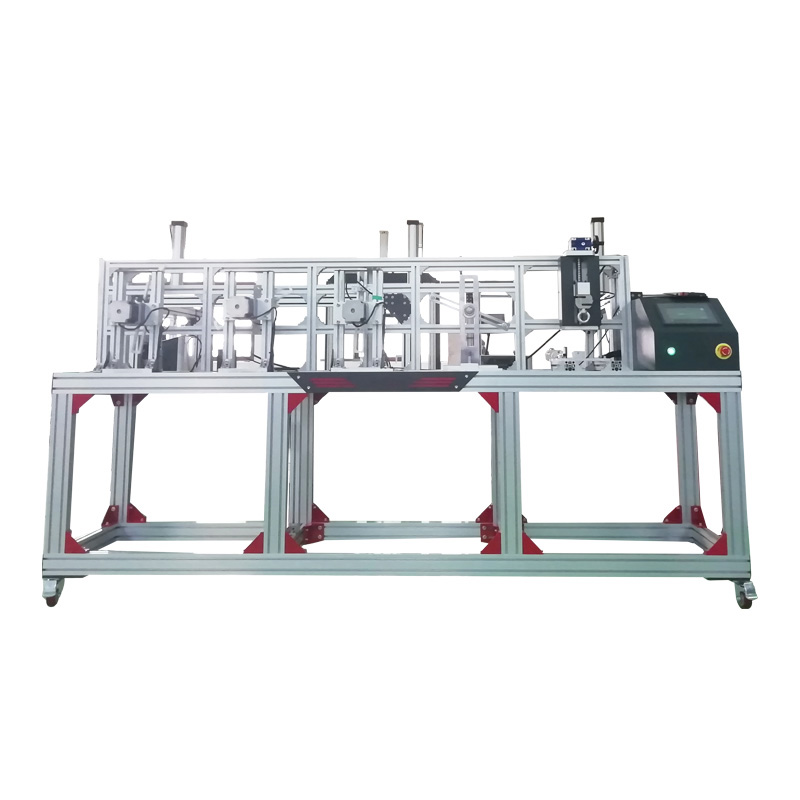

Product description

Professional testing equipment specially designed for testing single-point locking systems of doors and Windows, mainly used to evaluate the mechanical performance and fatigue life of lockers under long-term repeated use conditions. This device conducts systematic tests on the durability, reliability and operational performance of the lockers by simulating the repeated locking actions of doors and Windows in daily use.

Technical parameters

1. Structure: Aluminum profiles

2. Fatigue from repeated opening and closing

3. Transmission mode: Rotating cylinder

4. Torsion Angle: Adjustable from 0 to 180 degrees

5. Torsion speed: Adjustable from 0 to 20 times per minute

6. Control mode: PLC+ touch screen

7. Volume: Length 1.0* Width 0.5* Height 1.8 meters

8. Power Supply: AC220V, 50HZ

Comply with the standards and terms

| Category | Standard name | Standard clauses |

| Single-point locking device for building door and window hardware | JG/T 130-2017 | 4.4.4 Repeated opening and closing |

| Single-point locking device for building door and window hardware | JG/T 130-2017 | 5.4.4 Repeated opening and closing |

Test method

4.4.4 Repeated opening and closing shall meet the following requirements:

a) The single-point lockout type I should still be able to open and close after 150,000 repeated opening and closing tests. The operating force should meet the requirements of 44A).

b) After 150,000 repeated opening and closing tests of the single-point lockout type II, it can still be opened and closed, and the operating torque should meet the requirements of 4.4.1b);

C) After 50,000 repeated opening and closing tests of the single-point locker form, it can still be opened and closed, and the operating torque should meet the requirements of 441c).

5.4.4 Repeated opening and closing shall be carried out in accordance with the following provisions:

a) Install the single-point lockout type I and single-point lockout type II in accordance with the actual usage state and ensure that the lock hook does not collide with the lock seat during movement. Test

The verification frequency is 10 times /min to 15 times /min. After completing 5,000 repeated opening and closing tests, measure the operating force or operating torque according to the method in 5.4.1.

b) Install the single-point locking device form Ⅲ on the rigid component, with the complete retraction and extension of the locking part as one cycle, and the test frequency is 10 times /min to 15 times

After completing 50,000 repeated opening and closing cycles per minute, measure the operating torque according to the method in 5.4.1.

Last Article:Cover plate (cover ring) impact resistance testing machine

Next Article:Multi-point Locker Fatigue Testing Machine