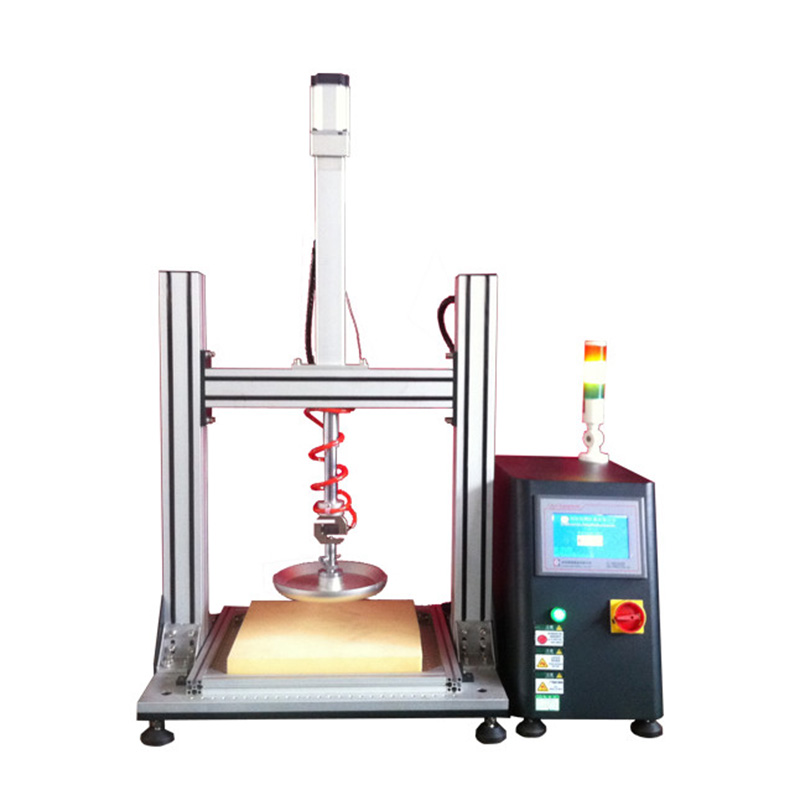

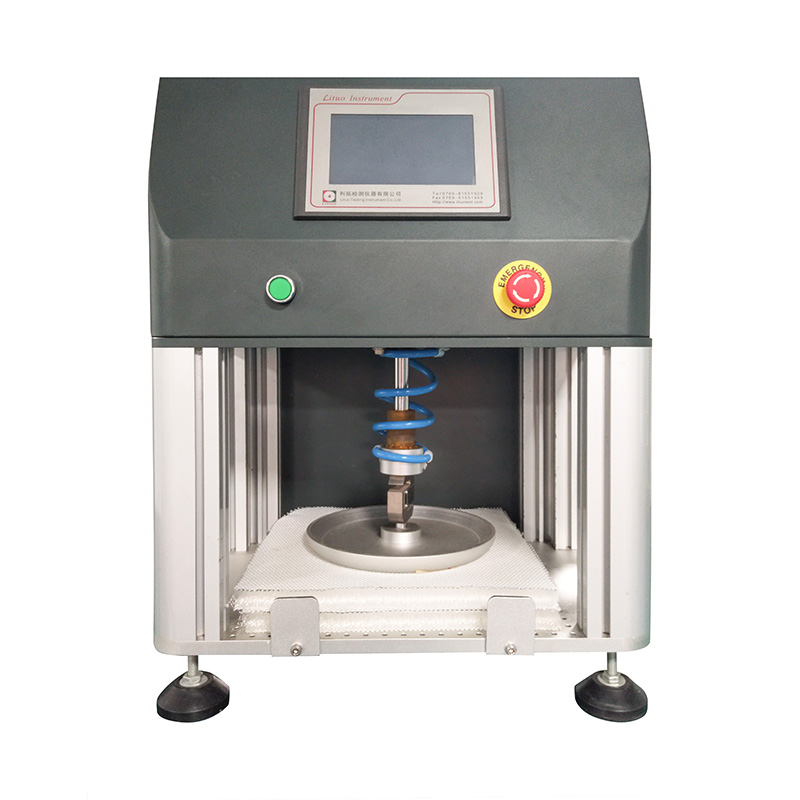

Product description

Sponge foam sag hardness tester is called compression testing machine, foam sponge sag hardness tester, for metal and nonmetal, polymer materials, such as tensile, compression, bending, such as low cycle fatigue test of the project, can according to customer's product requirements according to GB, ISO, ASTM, JIS and EN standards, can automatically calculate the maximum test force, fracture strength, yield strength, tensile strength, compressive strength, bending strength, elastic modulus, elongation, elongation stress, set the parameters such as stress and elongation.

Conform to the standard

In accordance with GB/ t10807-89,ISO 2439-1980 standards related requirements.

Product features

| 1. Automatic zeroing: after the computer receives the instruction to start the test, the system automatically zeroing. | ||

| 2. Automatic return trip: the sample will automatically return to the initial position after fracture. | ||

| 3. Automatic gear shifting: different gears can be switched according to the size of the load to ensure the measurement accuracy. | ||

| 4. Change the speed: the machine can change the test speed arbitrarily according to different samples. | ||

| 5. Indicator calibration: the system can realize accurate calibration of force value. | ||

| 6. Control method: test force, test speed, displacement, strain and other test methods can be selected according to test needs. | ||

| 7. Multi-purpose for one machine: equipped with sensors of different specifications, multi-purpose for one machine can be realized. | ||

| 8. Curve traversal: after the test is completed, the point-by-point force and deformation data of the test curve can be found with the mouse and analyzed. | ||

| 9. Display: dynamic display of data and curve test process. | ||

| 10. Results: the test results can be accessed and the data curves can be analyzed. | ||

| 11. Limit: with program control and mechanical limit. | ||

| 12. Overload: automatically stop when the load exceeds the rated value. |

Technical parameters

| 1. Maximum test tension: 1KN, 2KN, 3KN, 5KN |

| 2. Relative error of indication (no more than) : ±1% |

| 3. Relative displacement error: ±1% |

| 4. Relative deformation error: ±1% |

| 5. Measurement range: 1%-100% of the whole process is not graded |

| 6. Displacement speed: 0 ~ 500mm/min stepless adjustable |

| 7. Effective test trip: 0 ~ 140mm |

| 8. Effective test width: 360mm |

| 9. Resolution: 1/200,000 |

| 10. Control mode: force, displacement, deformation, three closed-loop control |

| 11. Power supply voltage: 220V 50HZ |

| 12. Overall size of the testing machine: about 390*670*950mm |

| 13. Machine weight: about 200Kg |

Last Article:Anti-ignition Characteristics of Mattresses and Sofas Testing Machine

Next Article:Spring compression fatigue tester | Spring repeated compression testing machine