Product description:

This machine simulates a match flame source to evaluate the anti-ignition characteristics of soft furniture.

Comply with standards:

It complies with the relevant requirements of the GB17927.1 ~ 2-2011 standard "Evaluation of Ignition Resistance of Soft Furniture - Part 1: Smolding Cigarettes and Part 2: Simulated Match Flames".

Technical parameters:

Simulate a match flame

A. Ignition source system: Two sets of stainless steel combustion tubes with an inner diameter of (8±0.1mm), an inner diameter of (6.5±0.1mm), and a length of (200±5mm) are provided.

b. Hose: The length should be (2.5-3mm), the inner diameter should be (7±1mm), and it should be connected to the stainless steel combustion pipe.

c. Flow control system: It includes a flowmeter, a fine-tuning valve, a on-off valve and a pressure regulating valve.

d. To meet the requirement of a flow rate of (45±2) m ³ /min, the nominal output pressure provided by this system is 2.8kpa.

e. Timing range: 0-999 seconds. It can respectively display and record the time of continuous burning or smolding, the time of fabric cracking, and the time of specimen extinguishing.

f. Test distance of the igniter: adjustable from 20 to 80 degrees, with an ignition mechanism that automatically moves and evacuates.

g. Flow measurement range: 10 to 100m ³ /min.

2. Smoldering cigarettes

a. Cigarette ignition source.

b. The cigarettes are cylindrical cigarettes with a filter or with the filter and interface removed, and meet the following requirements: Length: 60±5mm; Diameter: 8±0.5mm Mass per unit length: (0.6±0.1) g/50mm.

c. Cigarette burning time: (12±3) min/50mm.

d. Among the same type of cigarettes, every 10 cigarettes form a group. Randomly select one cigarette and measure the burning time of the cigarette in the laboratory according to the following method: After pre-treating the cigarette, take one cigarette and mark it 5mm and 55mm away from the ignition end respectively. Insert a fine steel needle horizontally into the non-ignition end of the cigarette, with the insertion length not exceeding 11mm. Light the ignition end and test and record the time it takes for the cigarette to burn between the two marks.

3. Laboratory: 2.5 meters in length, 2.2 meters in width, and 2.5 meters in height, including ventilation ducts. Made of stainless steel.

4. Observation window: One large observation window made of tempered glass, surrounded by SUS304 stainless steel.

5. Gas flow regulation: Adjust the test gas flow to 45±2mL/min.

6. Timing: 0-99.99H/m/s can be set arbitrarily

7. Control System:

1) The computer control system allows for the setting and recording of test time, test frequency, smolaring time, etc. on the computer. It features high intelligence, guided menu operation, simplicity and intuitionness, making the test results more accurate.

2) Automatic ignition function (high-voltage electronic ignition).

3) By adopting the PLC mode and using all high-quality components, the system ensures high-quality, high-speed operation and advanced features. The test process adopts the imported PLC+PID fully automatic control mode, which is the most advanced, safest, most reliable and most convenient control method nowadays. Realize automatic detection control and complete the detection work automatically. The friendly display interface makes the detection work faster and more accurate. The upper computer is designed with configuration software and can automatically generate temperature control curves and output reports. Data collection and printing of test results.

4) Lenovo brand computer: Screen size: 18.5 inches, CPU model: AMD Athlon X2 190, CPU frequency: 2500MHz, Memory capacity: 2GB DDR3, Hard disk capacity: 250GB 7200 RPM, SATA2 graphics card chip: High-performance integrated graphics card shared memory capacity, optical drive type: DVD-ROM, operating system: WINDOWS XP, graphics card type: integrated graphics card.

5) One printer.

6) One set of software with free lifetime upgrades.

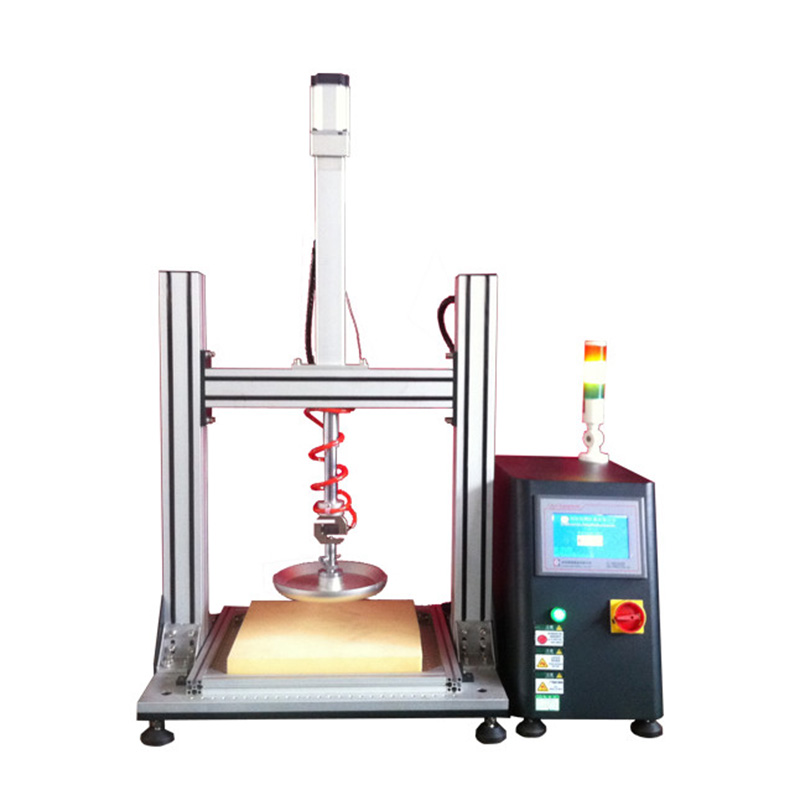

Last Article:Foam Rubber Reciprocating Compression Test Machine

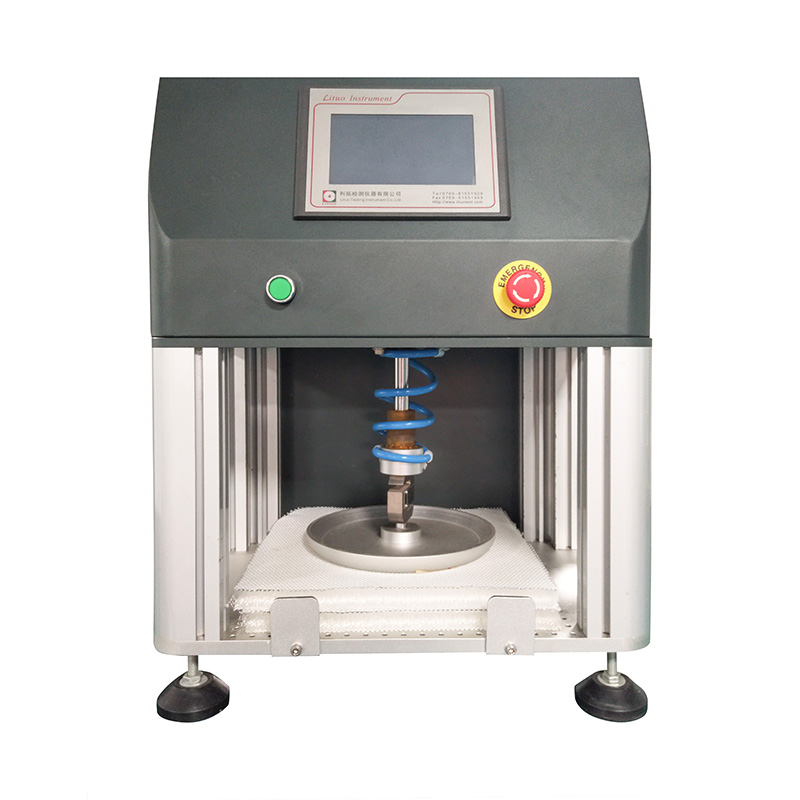

Next Article:Computerized sponge foam indentation hardness testing machine