Product description

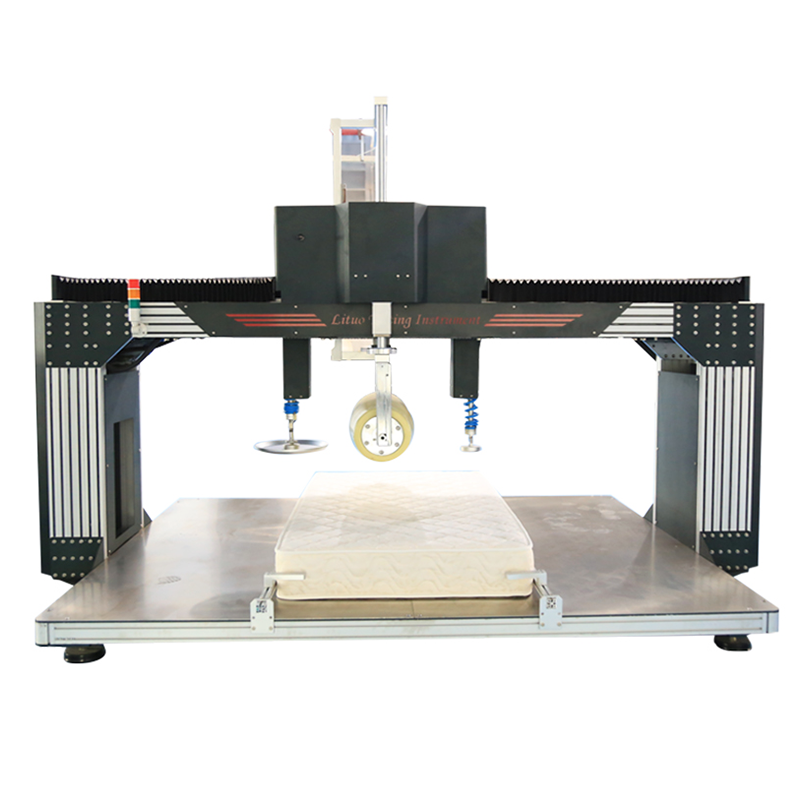

The national standard mattress surface durability testing machine is designed to simulate the continuous rolling during human sleep. The surface rolling durability is achieved by placing a rolling loading module on the horizontally placed loading part of the mattress and rolling it at a certain frequency to perform reciprocating loading on the mattress, in order to test the mattress's ability to withstand long-term repetitive rolling loads and meet the requirements of various mattress manufacturers and standards. It is used to determine the quality and service life of mattresses, strictly adhering to the requirements of national standards for mechanical testing. It is suitable for strong spring mattresses, ordinary spring mattresses, foam mattresses, brown fiber elastic mattresses, etc. This machine is mainly used for mattress height and surface durability tests.

Product features

1. This equipment meets two testing methods: pavement rolling durability test and test pad height test.

2. Controlled by a computer, it realizes fully automatic test results, with one-click control of both fully automatic operation and manual testing modes.

3. The pavement rolling durability test section adopts a gantry-type mechanical structure, using high-thrust servo motors and high-precision heavy-duty linear guides as transmission components. It is necessary to adopt well-known brand touch screens as input control to make the operation control more humanized, concise and clear.

4. The roller loading for the pavement durability test adopts the free loading of linear sliding bearings. The durability test adopts the free loading of the loading block + linear sliding bearing. Since only the rolling friction of the linear bearing exists, the accuracy of the loading force can be guaranteed. Therefore, the loading force is more in line with the standard requirements.

5. Elegant and generous appearance: Fully concealed wiring to prevent leakage during operation and any risks to the power system. The load-bearing surface is made of stainless steel plate with a smooth surface, which is convenient for loading mattresses. The all-steel plate base eliminates the need for drilling holes to fix the ground, fully ensuring that the instrument does not shift or shake during operation.

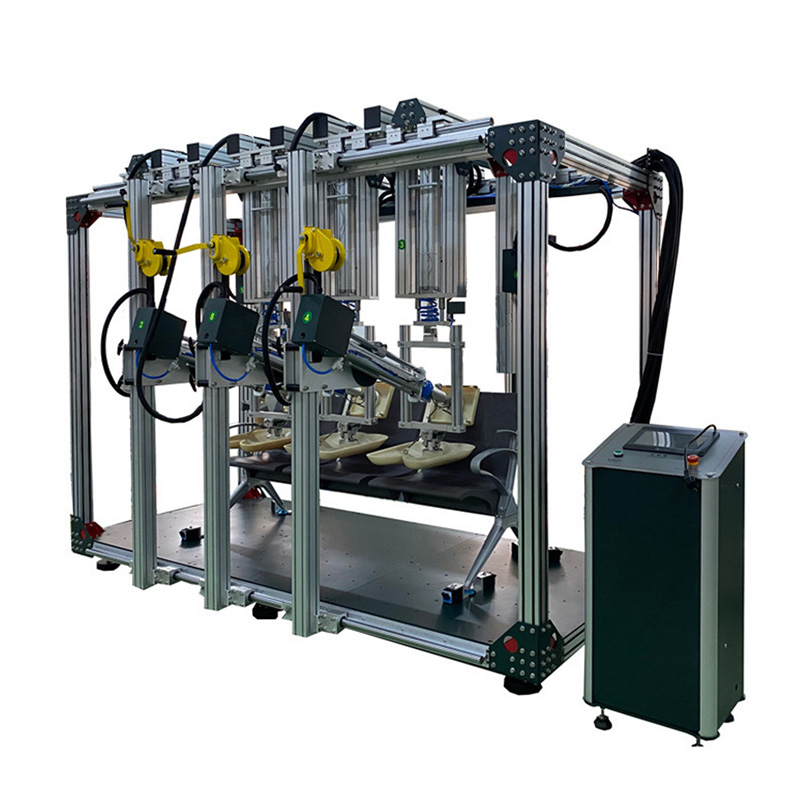

6. The test pad surface height test is driven by a servo motor, and the test is conducted at the speed specified by the standard. The curve graph between the force value applied by the loading pad on the specimen and the corresponding depression value is displayed, and the height is automatically measured.

7. The drum is made of special materials, which are highly wear-resistant, have a smooth surface, do not crack or deform, and have a long service life.

8. Midpoint positioning during the roll test: Automatically locate the midpoint of the mattress without the need for manual re-positioning. PLC starts point positioning.

9. The humanized control system features a simple interface and comprehensive functions. It uses a high-speed response touch screen for easy operation.

10. The test results can be printed out by a printer in the file format required by the customer.

11. Data Protection: Automatic data retention in case of power failure (Data can be automatically retained after power failure).

12. The base is made of high-strength industrial aluminum profiles and stainless steel SUS304 surfaces, which are connected together and will not rust for a long time.

13. The software displays the fatigue curve during the roller's rolling process, allowing for a direct view of the analysis of the mattress's indentation fatigue caused by the roller's load.

Comply with standards

This instrument complies with GB/T 26706-2011 "Soft Furniture - Brown Fiber Elastic Mattress". The requirements for mechanical tests in QB/T 1952.2-2011 "Spring Soft Mattresses for Soft Furniture" and BS EN 1957:2012 standards.

Technical parameters:

1. Control mode: Computer control

2. Pavement durability test device:

1) A mechanical device capable of driving the roller to move relatively horizontally on the surface of the mattress: The moment of inertia of the roller's rotation is (0.5±0.05) kg /m ², the loading frequency should be (16±2) times /min, the static load is (1400±7) N, and the test count is > 30,000 times;

2) Roller: Elliptical in shape, with an external dimensional tolerance of ±2mm. The surface should be hard, smooth, free of scratches and other surface defects. The length is (1000±2)mm, and the friction coefficient is between (0.2 and 0.5). The chamfer of the roller is R30, and the maximum diameter of the roller is 300±1mm.

3) Motor: Japanese Panasonic servo motor;

4) Test travel: 250mm on each side of the center line of the mattress;

5) The accuracy of the force measurement device shall not be less than 1%, the accuracy of the dimensional device shall not be less than 1mm, and the position deviation of the loading block shall be ±5mm.

3. Height measuring device:

Height measurement accuracy: ±0.5mm;

2) Height measurement pad: The measurement surface is a flat and smooth rigid cylinder;

3) Measuring the diameter of the pad: 100mm, chamfer R10;

4) Force application speed of the pad block: 100±20mm/min;

5) Vertical downward force: Apply a force of 4N. At this time, the distance between the lower surface of the measuring surface of the circular pad and the flat plate is the height of the mattress surface. Measuring height: The initial height of the mattress surface is measured. After conducting 100 durability tests and 29,900 durability tests, the height of the mattress surface is measured respectively. Height measurement system: The force value is set through software, and the force is applied vertically downward at a constant speed, directly connected to the PLC touch screen.

4. Appearance: Baked paint treatment

5. Material of the test bench: Stainless steel

6. The height of the test table surface from the ground: 180mm

7. Maximum test sample range: 2400mm×2400mm×440mm

8. Dimensions: 3320*2400*2280mm (length * width * height)

9. Test speed: 90mm/min; 100mm/min

10. Power supply and power: AC2201V, 50HZ, single-phase approximately 2KW

11. Weight: Approximately 2.3 tons

Last Article:Mechanical property testing machine for cabinets, tables and beds

Next Article:Mattress Rolling Test Machine