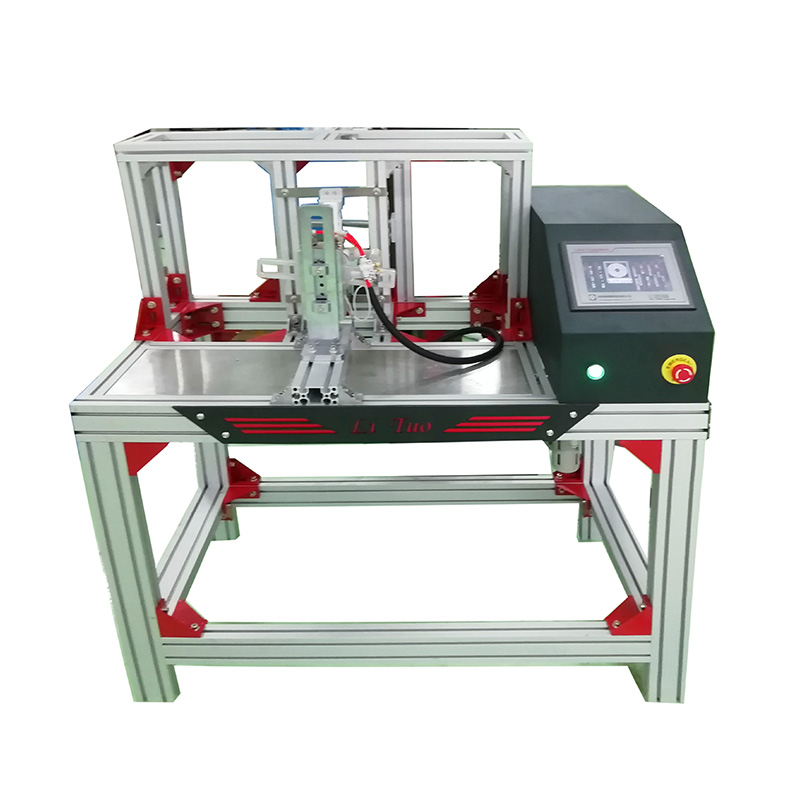

Product Introduction:

It is a portable and high-precision dynamic mechanical testing device, mainly used to evaluate the fatigue life, durability and operational comfort of various rotating operation components (such as valve handles, knobs, regulating switches, medical devices, etc.) under repeated torsional loads. This equipment simulates manual spinning actions (such as rotation, pressing, and reciprocating twisting) to detect the structural strength, wear characteristics, and failure modes of products. It is suitable for quality control, R&D verification, and industry certification.

Technical Parameter:

1. Structure: aluminum profile | |

2. Suitable for building Windows. | |

3. Transmission mode: rotating cylinder + push and pull cylinder | |

4. Torsion Angle: 0-180 degrees adjustable | |

5. Torsion speed: 0-20 times / minute is adjustable | |

6. Weight: 70N | |

7. Control mode: PLC + touch screen | |

8. Volume: length 1.0 * width 0.5 * height 1.0 m | |

9. Power supply: AC220V, 50 HZ |

4.4.4 Repeated opening and closing

After repeated opening and closing for 15,000 times, the change of the rotation position shall not exceed 0.5 mm.

5.5.4 Repeated opening and closing

Install the rotary handle and the mating block on the test simulation window in the actual operating state when the sash is closed (see Figure 3), and apply 70 + 8N force F in the opening direction of the handle.

Compliance with Standards and Terms:

Category | Standard name | Model Clauses | ||

Building doors and Windows hardware rotary press hold hand | JG/T 213-2007 | 4.4.4 Repeated opening and closing | ||

Building doors and Windows hardware rotary press hold hand | JG/T 213-2007 | 5.5.4 Repeated opening and closing | ||

Last Article:No More

Next Article:Lock Single-Point Handle Torque and Life Test Machine