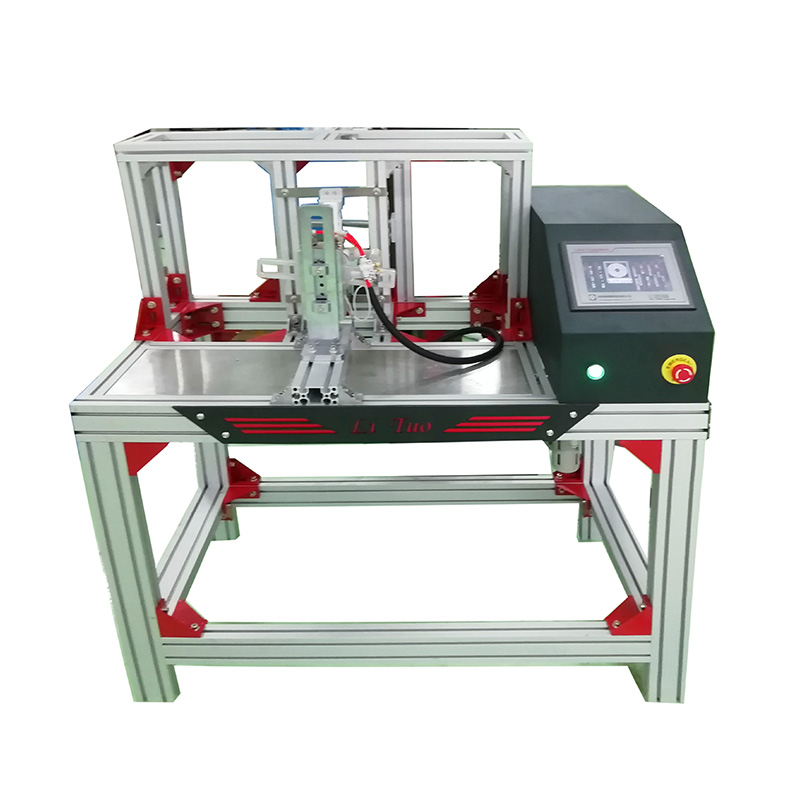

Product description

A professional testing device specially designed for testing the spinning handles (rotating handles) of doors and Windows, used to evaluate the mechanical performance, operational comfort and fatigue life of the handle products under long-term repeated use conditions. This equipment conducts systematic tests on the durability, operating torque and structural reliability of the handle by simulating the real scene of repeated rotation operations of the human hand.

Technical parameters

1. Structure: Aluminum profiles

2. It is suitable for spinning handles used in building Windows.

3. Transmission mode: Rotary cylinder + push-pull cylinder

4. Torsion Angle: Adjustable from 0 to 180 degrees

5. Torsion speed: Adjustable from 0 to 20 times per minute

6. Weights: 70N

7. Control mode: PLC+ touch screen

8. Volume: Length 1.0* Width 0.5* Height 1.0 meters

9. Power Supply: AC220V, 50HZ

Comply with the standards and terms

| Category | Standard name | Standard clauses |

| Spinning handles for building door and window hardware | JG/T 213-2007 | 4.4.4 Repeated opening and closing |

| Spinning handles for building door and window hardware | JG/T 213-2007 | 5.5.4 Repeated opening and closing |

Test method

4.4.4 Repeated opening and closing

After being repeatedly opened and closed 15,000 times, the change in the spinning position should not exceed 0.5mm.

5.5.4 Repeated opening and closing

Install the spinning handle and the mating pad block on the test simulation window according to the actual usage state when the window sash is closed (see Figure 3), and rotate the axis of the handle

Keep applying a force F of 70+8N along the opening direction of the window sash on the line. Measure and record the initial distance L1' between the frame and sash at the handle locking point at 250 times per hour ~

Operate the handle at a frequency of 275 times per hour for 15,000 repeated opening and closing operations. Check the damage of the handle every 5,000 times, measure and record the repeated opening and closing

The distance l between the frame and the sash at the handle lock. The change in distance Δ l' between the front and rear frames and sashes of the handle lock position when repeatedly opening and closing is calculated according to Equation (2).

Last Article:Spin Pressure Hand Holding Fatigue Testing Machine

Next Article:Single point handle and push lock fatigue testing machine