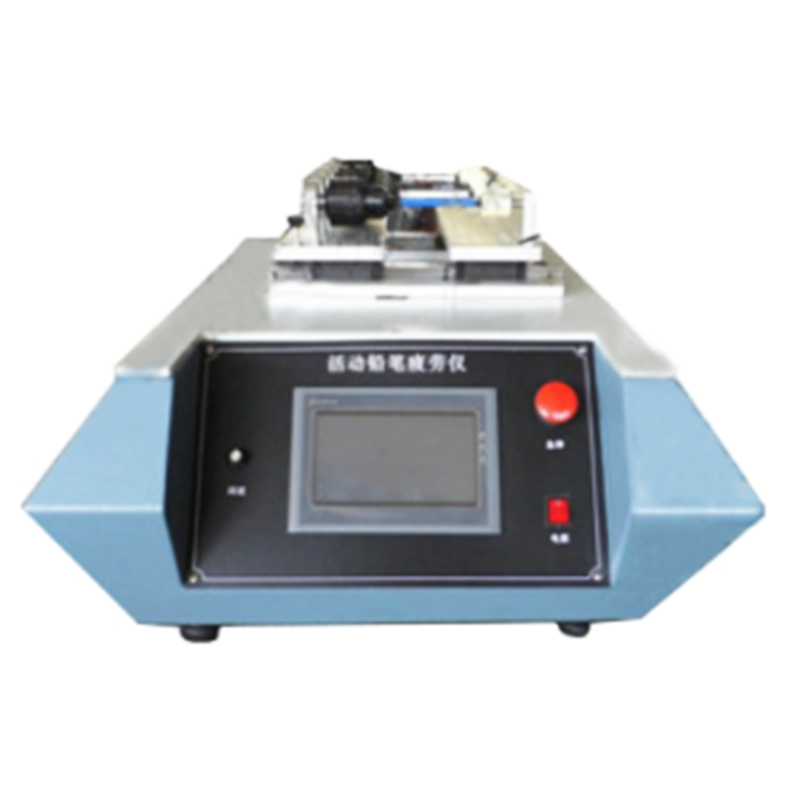

Product description

The manual pencil sharpener cutting torque tester is a precision instrument specifically designed to measure the torque required by a manual pencil sharpener during the process of cutting pencils. By simulating real usage scenarios, this device can accurately detect the frictional resistance and cutting torque value between the pencil sharpener's blade head and the pencil, providing a scientific basis for product quality control, performance optimization and durability testing. It is applicable to pen sharpener manufacturers, quality inspection institutions and R&D laboratories.

Comply with standards

GB/T22767-2008 "Manual Pen Sharpener"

Working conditions

AC 220V,50Hz, room temperature: 15-30℃ Relative humidity: 20-80%RH.

Technical parameters

1. The output power of the motor is ≥75W

2. The rotation speed of the tool rest is manually set from 0 to 150RPM (the standard value is 100R/min).

3. The transmission force value during cutting is set at 2.5 ± 0.5N

4. The torque accuracy reaches ± 0.5%, and the maximum value is retained. Available for comparison

Product features

1. Set the torque alarm value arbitrarily (the standard requirement is that the torque is less than 78.5N.m)

2. The unit can be freely selected as kgf-cmN.m. Or kgf-cmLb.inch.

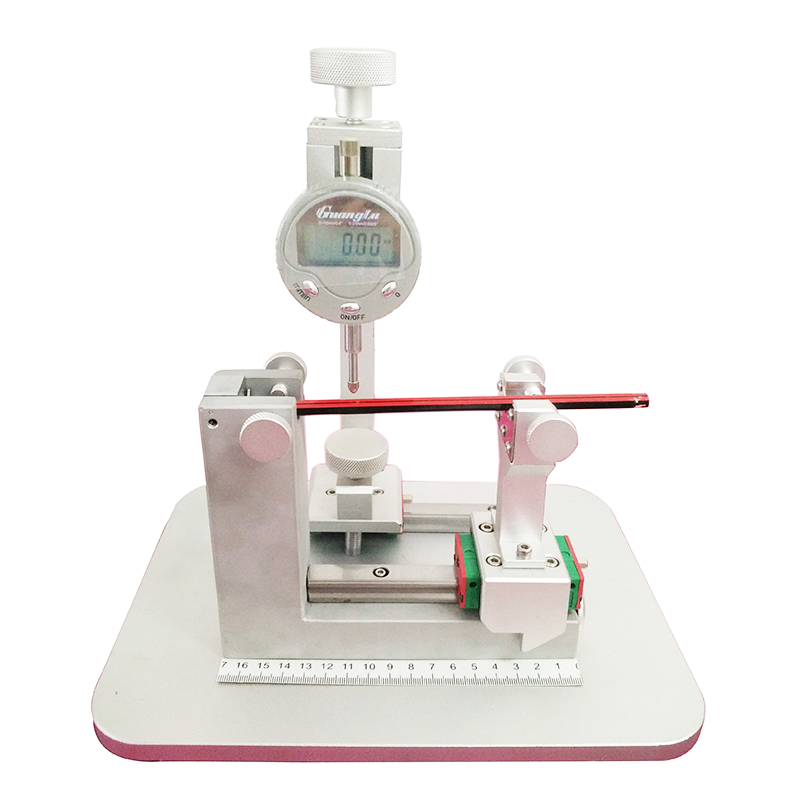

3. Fix the pen on the fixture, then remove the knife and the tool rest from the test pen sharpener, measure the maximum value of the torque measuring instrument during the cutting process, repeat three times, and calculate the average value.

4. Controlled by imported PLC, 7-inch touch screen display, and data storage via USB flash drive. Computer data analysis

5. Adopt dynamic torque sensors imported from the United States

6. Servo motor drive

Last Article:Special marking testing machine

Next Article:Sliding core tester