Product description

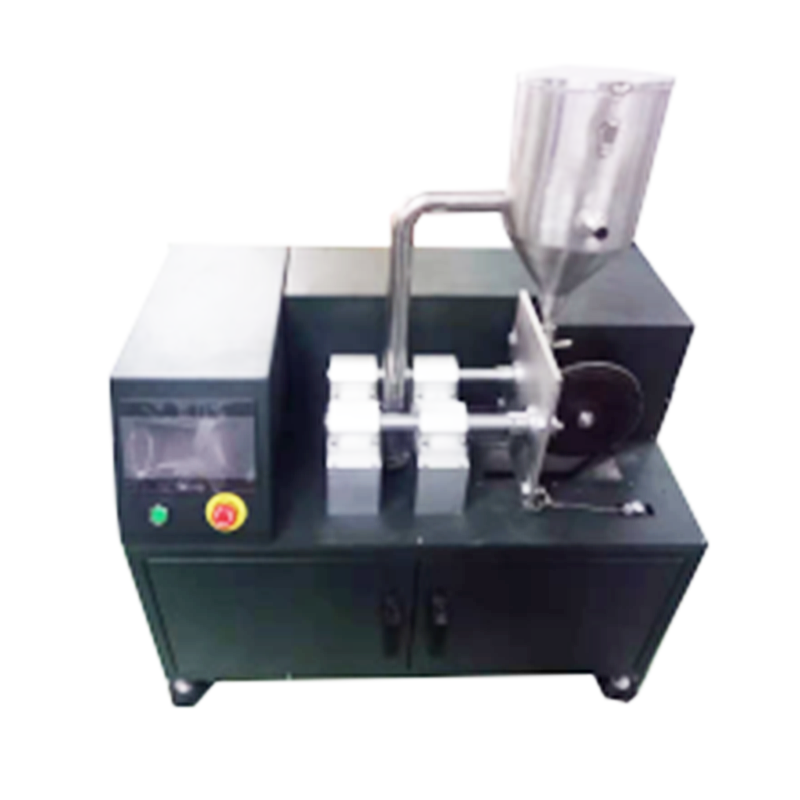

Precision testing equipment specifically designed for inspecting the surface wear resistance of unglazed ceramic tiles, natural stone, concrete bricks and other materials. This instrument quantifies the wear resistance grade of materials by simulating the friction and wear they encounter during daily use, providing a scientific basis for product quality control, industry standard certification and engineering material selection.

Technical parameter

1. It is used to produce the grinding pit by rotating the front of the brick in the condition of abrasive. The wear resistance of the unglazed brick is determined by the length of the measured grinding pit.

2. The equipment includes a friction steel wheel, a storage bucket with an abrasive feeding device, a sample fixture and a balance hammer.

Friction steel wheels are manufactured with ISO 630-1 steel (above HB 500) with diameter of 200mm±0.2mm and edge thickness of 10mm±0.1mm.

4. Speed of friction steel wheel: 75 r/min ± 5 r/min.

5. The abrasive is corundum (molten alumina) with F80 in accordance with ISO 8464-1.

6. The abrasive feeding rate is 100g / 100r ± 10g / 100r.

7. The hopper volume shall not be less than 5L.

8. The equipment shall have the function of counting and preset the number of friction steel wheel, and can be tested automatically in the design time.

9. Equipped with friction steel wheel consumables that meet the two-year service cycle of the equipment (according to 5000h).

Compliance with the standards and terms

| Category | Standard Name | Model Clauses |

Test method for ceramic bricks Part 6: Determination of the wear-resisting depth of unglazed bricks | GB/T 3810.6-2016 | 4.1 Wear-resisting test machine |

| Test method for ceramic bricks | ISO 10545-6:2010 | 4.1 Wear-resisting test machine |

| Test method for wear resistance of inorganic ground materials | GB/T 12988-2009 | 4.1 Steel wheel grinding tester (note: optional table) |

Last Article:No More

Next Article:Ceramic Brick Friction Coefficient Testing Machine