Product description

Suitable for electronic and electrical, instrumentation, home appliances and other products, parts and materials in the temperature change (cold and heat shock) environment storage, transportation, use adaptability test (reliability test)

Equipment characteristic

1. Pre-cooling temperature range in low temperature zone: -65ºC ~ 0ºC.

2. High temperature zone preheating temperature range: +60ºC ~ +200ºC.

3. High and low temperature conversion time: 5min.

4. Temperature fluctuation: ±0.5ºC.

5. Temperature uniformity: ≤±2.0ºC.

6. Test holding time: >=15min (adjustable).

7. Energy storage area rising and cooling rate:

Average cooling rate in low temperature zone: (0.7 ~ 1.5) ºC/min.

Average heating rate in high temperature zone: (3.0 ~ 6.0) ºC/min.

8. Test weight: 15 KG (other specifications can be customized).

9. System noise: 68 DB.

10. Power supply: AC3 5W 380V±10%; 50HZ.

11. Use air source (compressed air) : pressure: (5 ~ 7)kg/cm2

12. Power: 18.5KW.

13. Maximum working current: 35.0A.

14. Weight: 900KG

15. The rate of temperature change is the average rate of air temperature change, rather than the rate of surface or internal temperature change of the product.

16. The performance measured after 20 minutes of stability without test load and without shelf.

17. The temperature sensor is set in the circulation motor outlet.

18. Temperature uniformity is defined as the data measured at the geometric center point of the experimental machine (measurement unit space 9-point temperature measurement method).

19. Equipment fault protection: overheat protection circuit breaker, leakage protection, compressor overload protection, control system overload protection, phase sequence

Protection, water shortage protection, high pressure and low pressure protection, over temperature protection, fan overcurrent protection.

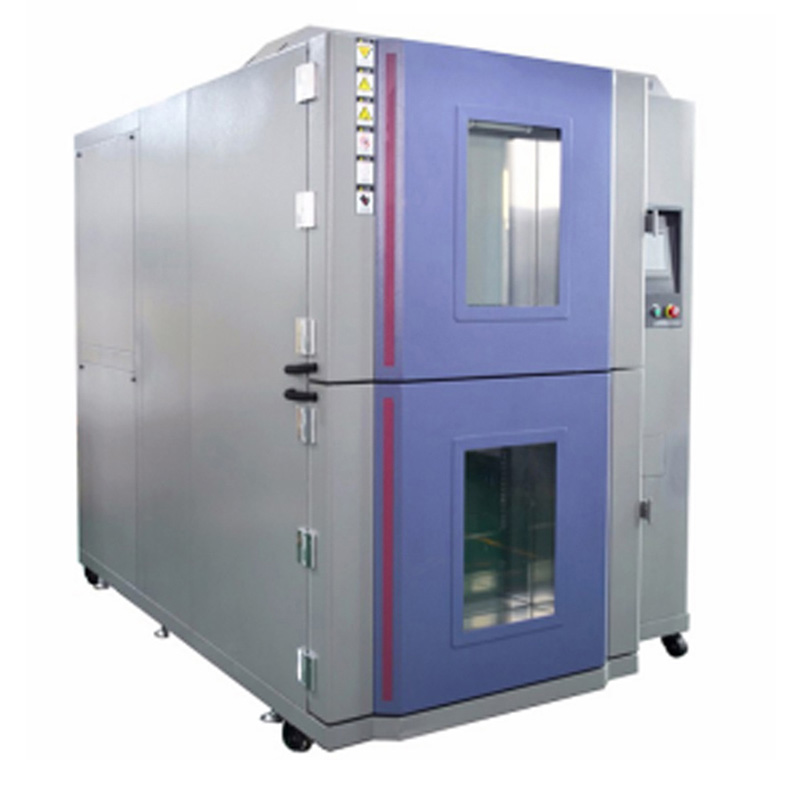

Structure of equipment

1. Basket size: W2000*D700*H200 (mm).

2. External dimensions (approx.) : W3100*D1400*H1900 (mm).

3. Case material: a. Outer box material: Baosteel high-quality steel plate electrostatic spray treatment; b. Inner box material: SUS304# heat-resistant and cold-resistant stainless steel plate.

4. Insulation material: polyurethane foam + high temperature rock wool board insulation.

5. Outer box base: national standard Angle iron + national standard channel steel + special anti-rust treatment of electrolytic plate spray.

6. Test box door (double door) :

a. Material: same as the test box.

b. Handle: stainless steel handle.

c. Rear button :SUS#304.

d. Test hole: there is 1 hole with a diameter of 50mm on the left side of the body, 1 stainless steel hole cover, and 1 silicone plug head.

7. Forced air circulation system: a. long shaft motor: AC220V 120KW extended shaft motor ×2 sets; b. Multi-wing wind turbine.

8. Heating system: Moisture-proof and low-temperature SUS316L stainless steel heating wire durable.

9. The equipment is equipped with air pressure balance and explosion-proof configuration, and the air pressure balance port balances the air pressure inside and outside the work room.

Last Article:Double Door Constant Temperature and Humidity Test Chamber

Next Article:No More